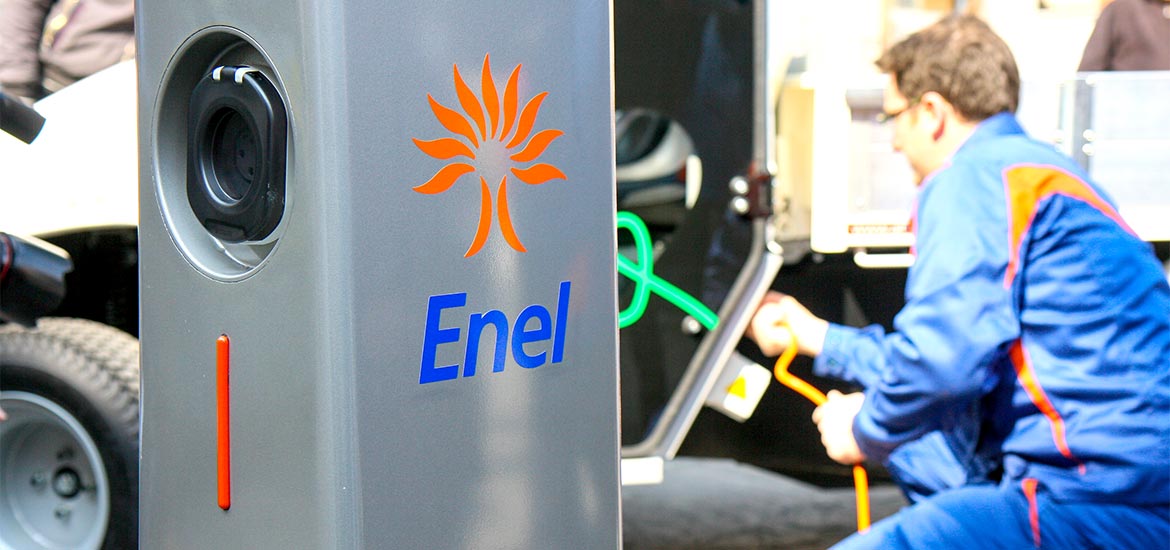

ENEL chooses Alke's electric work vehicles

Enel has been using Alke' electric vehicles since 2011. Enel is promoting both externally and internally a series of initiatives to support eco-mobility, thanks to "Electric Car. Zero Emissions", Enel's electric mobility project.

Why should you choose Alke vehicles for power plant

- Full electric: zero pollution and no noise

- Hundreds of configurations to choose from

- Optimal company fleet management

- Extremely robust: load capacity up to 1,630 kg (chassis) and towing capacity up to 4,500 kg (in private area)

- Extremely low running costs

Alke electric vehicles fleet for Enel power plants

Enel, Italy's largest energy provider, is taking action to promote sustainable mobility, thanks to an ambitious project to reorganise its corporate fleet towards zero-impact solutions. For this reason, Enel has chosen Alkè vehicles for its power plants. The first ones have been delivered to the Castel San Giovanni (PC) power plant and will allow employees to move around without producing emissions. This initiative is part of "Enel Drive", Enel's activity that takes the form of numerous pilot projects aimed at spreading electric mobility in Italy and creating a widespread and effective recharging infrastructure capable of interfacing with any electric vehicle. The vehicles chosen by Enel are the Alkè ATX with various types of equipment.

The characteristics of Alke' vehicles for power plants

These high-performance professional electric vehicles are fitted with a electric motor, capable of increasing power from 8 kW to 14 kW peak, to allow optimal operation even on uneven terrain and slopes of up to 35%. The autonomy on standard routes can be up to 200 km, which corresponds to an entire working day, even where multiple stops are required for frequent loading and unloading operations. The ATX electric work vehicles are equipped with a recovery motor brake system that prevents wasted power and brake wear when stopping. Complete recharging of the battery set, which is usually carried out during overnight shutdowns, is done using the high frequency charger on board the machine, which allows you to connect wherever you are.

When evaluating the ATX model, then chosen by Enel, a series of tests were carried out to verify its performance: Chassis strength test; Vehicle uphill start test; Battery autonomy test. These tests made it possible to simulate an intensive use of the vehicle inside the plant.

See photos in the official ENEL flickr channel