Hazardous area classification: location certification

The purpose of this article is to try to provide a summary of the most important certifications and regulations in terms of hazardous areas and answer the following question: which are the most important regulations in terms of hazardous areas?

Classification of hazardous areas and certifications

- ATEX Directives: 2014/34/UE and 99/92/CE

- Areas with explosion hazard due to the presence of gas

- Areas with combustible dust

- North American standards - Class/division classification

Alkè international references in the ATEX sector:

Hazardous areas: Alke provides certified explosion-proof vehicles

A hazardous area is a place where a potentially explosive atmosphere is created by the presence of a certain amount of flammable gas, vapour or dust during a certain period. In a hazardous area, equipment must be designed to avoid hazards and to establish safe working or living conditions. Uncertified electrical elements could be a risk factor and it is to prevent explosions and fires that many certifications are required. Alkè electric vehicle certifications follow current regulations and all our electric vehicles are tested and certified as explosion-proof. In fact, Alkè can provide certified explosion-proof electric vehicles that can operate in various hazardous areas such as chemical and petrochemical industries, oil and gas production sites, construction and maintenance, and many other sectors. The first purpose of this article is to try to provide a summary of ATEX zone classifications and regulations and answer the following question: Which are the most important directives in terms of hazardous zones?

ATEX Directives: 2014/34/UE and 99/92/CE

2014/34/EU regulates equipment intended for use in hazardous areas. The EU directive is aimed at manufacturers of equipment intended for use in areas with potentially explosive atmospheres and manifests itself in the mandatory certification of these products. Directive 99/92/EC for the safety and health of workers in explosive atmospheres applies in explosive atmospheres, where certified plant and equipment is put into operation. The purpose of Directive 99/92/EC is to provide the minimum requirements for improving the safety and health protection of workers exposed to the risk of explosive atmospheres.

ATEX Zone Classification: Gas

Gas zones are usually divided into:

| Non-dangerous area | In chemical, petrochemical or other industries, where it is absolutely certain that hazardous gases are present, a concentration of less than 25 per cent of its lower flammability limit (or lower explosive limit) is indicated. A non-hazardous zone is a place where no explosive or flammable gases are present and gases from cleaning products, for example, could pose the main risk. These zones are areas identified as offices or residences and are classified as safe areas. This class presents a low risk of explosion or fire. |

| Zone 2 | Area 2 is more risky than a safe area. In these areas, the presence of gases or vapours can only be detected under abnormal conditions. In this case, the hazardousness of the areas is determined by the low presence of hazardous gases (or vapours) and, these undesirable substances, must be present for less than 10 hours/year or less than 0-0.1 per cent of the time. |

| Zone 1 | This is an area where vapours or gases are present, under normal conditions, for long periods. In Zone 1, substances may be present for 10-1000 hours/year or 0.1-10% of the time. |

| Zone 0 | Zone 0 is an area in which undesirable hazardous substances (gases or vapours) are always present. According to the Directive's definition, Zone 0 is an area where explosive or flammable gases or vapours are present for more than 1000 hours/year or more than 10% of the time. |

ATEX Zone Classification: Dusts

The ATEX classification divides the areas at risk of dust combustion into three types of areas:

| Zone 22 | Area in which the formation of an explosive atmosphere, in the form of a combustible dust cloud, is not likely to occur, or only for short periods. |

| Zone 21 | Area where the explosive dust cloud normally persists during routine operations. |

| Zone 20 | High explosion hazard area in which a cloud of combustible dust is constantly (or for long periods or frequently) present in the atmosphere. |

North American Standards - Area Description and Class/Division Classification

In North America, unlike the ATEX Directive, products are divided into Classes and Divisions. Guidelines are provided by the National Electrical Code (NEC). In the USA, equipment manufactured for use in hazardous areas is tested and approved by nationally recognised testing centres such as Underwriters Laboratories (UL).

| Class I: gases, liquids and vapours | An environment in which the concentration of flammable or explosive gases, vapours or liquids is present continuously or frequently during normal operation is classified as Class I / Division 1. An environment in which the same unintentional concentration of flammable substances is present only under abnormal operating conditions is classified as Class I / Division 2. |

| Class II: dusts | Class II / Division 1 covers dust. In this category are all areas where there is a concentration of combustible dust in the ambient atmosphere during normal operations. Class II/Division 2, in this class, combustible dusts are only present in the atmosphere under abnormal operating conditions. |

| Class III: fibres or materials | Class III / Division 1 defines areas where fibres or materials that produce combustible fumes under normal conditions are present. Class III / Division 2 defines areas where flammable fibres or materials that produce combustible fumes under exceptional conditions are present. |

Classification of specific protections

Suitable equipment is required to work in hazardous environments. Specific authorities test and certify equipment according to classification standards. The specific process of classifying equipment into categories (Category 1, Category 2 and Category 3) is based on the equipment's level of protection. In this classification, Category 1 represents the highest safety level, Category 2 the lowest. Category 1 equipment is used in zones 0, 1 or 2, Category 2 equipment is used in zones 1 or 2 and Category 3 equipment is used only in zone 2. Different countries use different procedures for labelling.

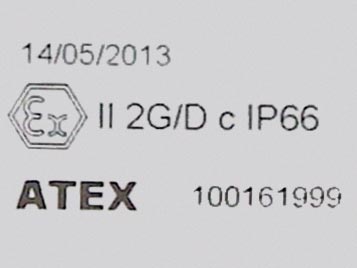

In Europe, a label bearing the ATEX certification and CE signature combined with the Ex marking is used.

The label must indicate the Group, the Category and, if it is Group II equipment, the indication of gas (G) or dust (D).

In North America, a nationally recognised testing laboratory (such as UL, MET, FM, CSA) must test and certify the equipment for a specific hazardous area.

The label shows the Class(es), Division(s) and sometimes the Group(s) and Temperature Code.

Next to the label you can find the mark of the certification agency.