The most cost-effective electric vans

Discover the most cost-effective electric vans. Innovative commercial vehicles with compact dimensions but high loading and towing capacity.

Why Alke' is the most cost-effective electric van

- Top quality: Italian or European suppliers; scrupulous quality control

- A strong focus on innovation and technology.

- Agile and compact: only 140 cm wide

- Load capacity: up to 1,630 kg (chassis)

- Towing capacity: up to 4,500 kg

Quick guide

Alke' electric vehicles

Quality control and inspection of Alkè vans

Alke' carries out a quality check of its vans one by one before they leave the plant, in order to offer 100% robust, safe and high quality electric vehicles. The check covers every part of the vehicle from electrical to mechanical, batteries and fluid levels. The tests are carried out both on the road and at Alke plant which, with its 11,000 m2 and its specific test track, allows all the tests necessary for the final check to be carried out. Alke has always pursued the objective of guaranteeing high quality in production control, both at the level of individual components and pre-assemblies, and for each vehicle produced. All suppliers are in fact Italian or European, able to guarantee the highest quality and rapid and flexible support for any new development.

The main control activities on Alke' electric vans

| Fluid level | Check the level is right and that there are no leaks in the system. |

| Chargers and batteries | A full charge cycle is performed, after which the batteries are checked to ensure they are charged and that there are no faults on the charger. |

| Electrical system | All components are tested individually. The various devices are switched on and checked for proper functioning. |

| Braking system | Dynamic testing of the service and parking brakes is carried out on the test track at the Alkè factory: For the service brakes, the reaction of the vehicle to sudden braking is tested. The handbrake is tested by pulling it while driving. In this case the motor must brake and the vehicle must stop. It is also pulled when the vehicle is stationary and must brake when vans attempt to accelerate. |

| Mechanical parts | Check that all nuts and bolts are properly tightened. |

Innovative approach and state-of-the-art technology

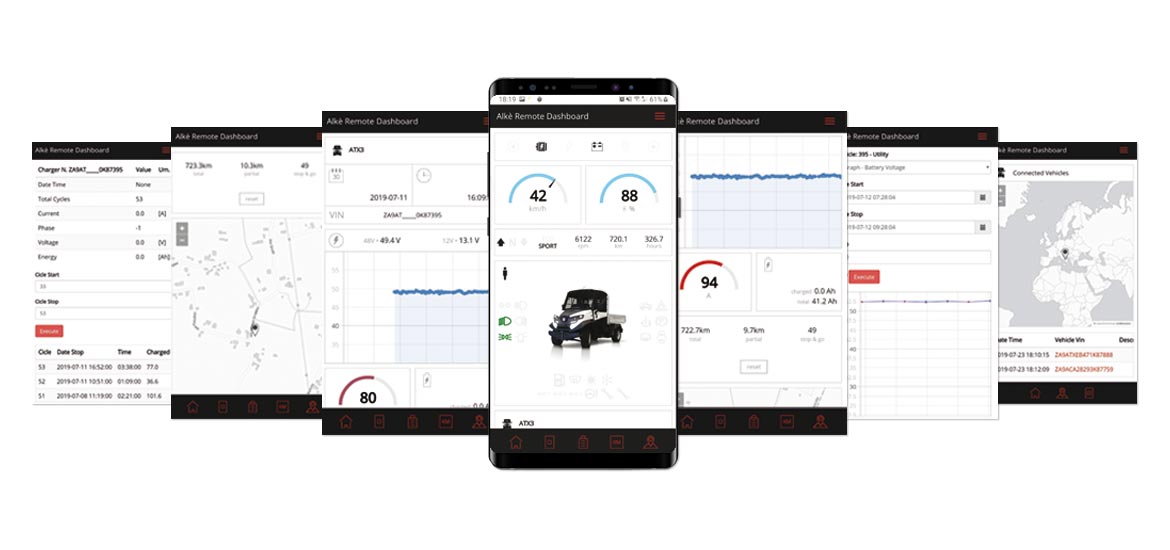

In addition to the tests carried out on each van before delivery to the customer, Alke's experts and engineers also carry out a series of tests to verify specific van performances, such as ramp tests, tests in certain weather conditions, tests on batteries and other electronic components, in order to ensure continuous improvement and to offer innovative solutions. This is why Alkè collaborates with international research projects with the aim of developing new solutions that can also be applied to its electric vehicles. From a technological point of view, Alkè vans can be equipped with a Vehicle Body Computer (VBC) that connects all the vehicle devices to the Alkè cloud platform for real-time monitoring of on-board activities, as well as allowing remote diagnostics, again in real time, in the event of anomalies.